|

Reinforced platform which allows you to calculate the weight of a vehicle in transit, summing the various axles, weighed when stationary or in motion. Designed for a flush floor installation. Reinforced platform which allows you to calculate the weight of a vehicle in transit, summing the various axles, weighed when stationary or in motion. Designed for a flush floor installation.

CE approved according to Directive 2014/31/EU for verification of the axle weight.

Technical FEATURES

- Loading surface in striated sheet steel, sized to withstand any load on the basis of the parameters dictated by the Directive 96/53/EC (maximum load on single axle for vehicles transiting in Europe).

- Frame for the containment of RWSCP platform, made up of a single bearing structure, in welded painted steel, that does not require assembly. It facilitates the installation of the scale and simplifies the masonry.

- Sandblasting and varnishing with bi-component epoxy coating, highly resistant to corrosion.

- Dimensions of the load surface (lxw): 3 x 0.73 m.

- 6 compression load cells, class C3, stainless steel IP68.

- 20m cable for connection to the weight indicator.

- Dust and waterproof wirings and connections, easy to connect and disconnect.

- Hermetic junction box.

- Central inspected trapdoors for the ordinary maintenance.

- Wide range of connectable weight indicators, also functioning with rechargeable battery, which allow to use the platform also without an electrical power supply.

- Maximum speed of transit: 5km/h.

- Accuracy 1% for internal use, 2% for legal-for-trade use.

This kind of accuracy is obtainable by following the instructions in the installation manual.

Great versatility of use

- The axle weighing system is ideal to:

– Weigh any type of vehicle regardless of the number of axles.

– Check the weight of the material transported by the vehicle and carry out simple checks on incoming/outgoing goods.

– Check the weight of each axle or of all the various sums of weights.

– Check the presence of any vehicle overloads, avoiding incurring penalties.

Certifications and approvals

- The system is CE approved according to Directive 2014/31/EU (NAWI, static weighing) for verification of the axle weight.

- The system is also OIML R134 certified for in-motion weighing (dynamic) of the whole vehicle, at a maximum speed of 5km / h with a weighing accuracy of 2% (sum of the weight of the axles, depending on the rules in force in the country of use).

- The system is approved in Italy as a weighing instrument with automatic operation, for in-motion road vehicle weighing according to Decree no.267995 of 19/9/2019.

- The system is also approved for dynamic weighing in various European countries (for further information please contact our sales office).

Stationary and In-motion Weighing

- The stationary weighing function allows the vehicle to be weighed by adding up the weights of the individual axles.

As well as being the most cost-effective way to weigh, it avoids penalties due to axle overloading.

- The in-motion weighing function allows you to minimize weighing time.

The weight is acquired as the vehicle passes over the scale, without the need to stop for weighing each axle.

In-motion weighing is particularly suitable for those who need to weigh frequently during the day.

Technologically Advanced Weight Indicator

- The touch screen weight indicator simplifies the use of the scale and allows the introduction of personal data. With integrated printer or USB communication port to save the weighs.

Programmable digital inputs and outputs are also available, to realize automations or to pilot bars, traffic lights etc.

Available Functions

|

Reinforced platform which allows you to calculate the weight of a vehicle in transit, summing the various axles, weighed when stationary or in motion. Designed for a flush floor installation.

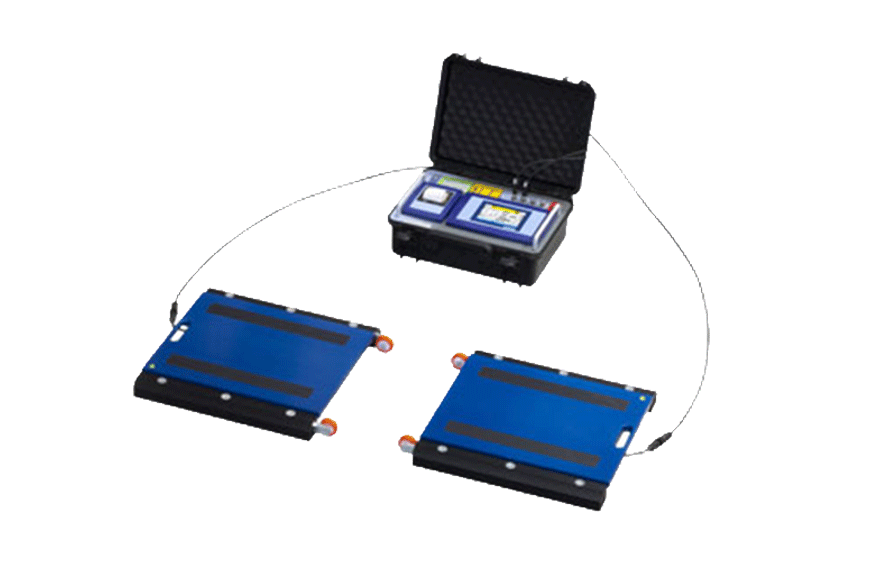

Reinforced platform which allows you to calculate the weight of a vehicle in transit, summing the various axles, weighed when stationary or in motion. Designed for a flush floor installation. It weighs the vehicle axles and calculates the total weight. Consisting of two WWS series portable pads and the touch screen weighing terminal with integrated printer. Wired version.

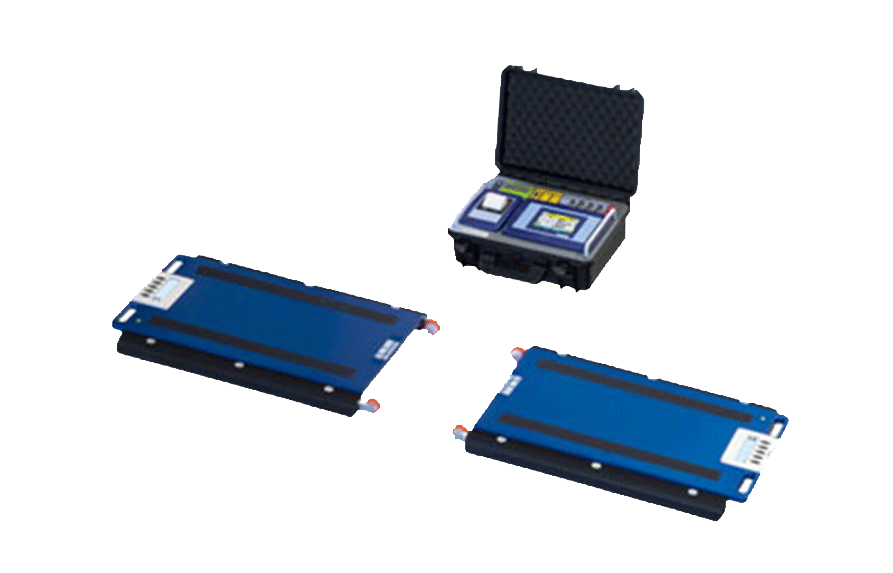

It weighs the vehicle axles and calculates the total weight. Consisting of two WWS series portable pads and the touch screen weighing terminal with integrated printer. Wired version. Weighs the vehicle axles and calculates the total weight. Consisting of two WWS series portable pads and the touch screen weighing terminal with integrated printer. Wireless version.

Weighs the vehicle axles and calculates the total weight. Consisting of two WWS series portable pads and the touch screen weighing terminal with integrated printer. Wireless version.